Aug 29, 2019

How To Repair A Tire

It has happened to most of us. You're on your way to the store or driving home from work and you hit some sort of debris in the road, puncturing your tire, and leaving you with a flat.

Although the tire is flat and must be brought to a tire repair shop, like Sullivan Tire and Auto Service, for an inspection, the tire may not necessarily need to be replaced. Depending on where the puncture is located along with the severity of the damage, the tire will either only need a simple repair or will be replaced.

Sullivan Tire and Auto Service abides by the tire repair guidelines of the U.S. Tire Manufacturers Association (USTMA, formerly known as the Rubber Manufacturers Association) and Tire Industry Association (TIA).

Repairable Tires

A tire can be repaired if:

- It is punctured within the puncture repair area of the tire (pictured under the "non-repairable tire" section below)

- The puncture doesn’t measure more than 1/4 of an inch in diameter

- The repairs do not overlap or if the injuries are not directly across from each other

Tire Repair Process

- Remove the tire from the rim

- A thorough inspection of both the inside and outside of the tire

- Although a tire may appear to be a simple fix from the outside, the bottom half of the nail could have caused potential damage to the interior sidewall

- Once deemed repairable, trim the puncture area of damaged cables to clean and stabilize the area

- From the inside out, pull a rubber stem through the puncture area sealing off the inside of the tire

- From the inside, buff the puncture area then apply special vulcanizing glue

- A patch is then installed on the inner liner over the puncture area causing a chemical reaction

- The tire is then mounted back on the rim, inflated to the proper tire pressure and the repair is checked for leaks

This procedure takes 60-90 minutes to be done properly.

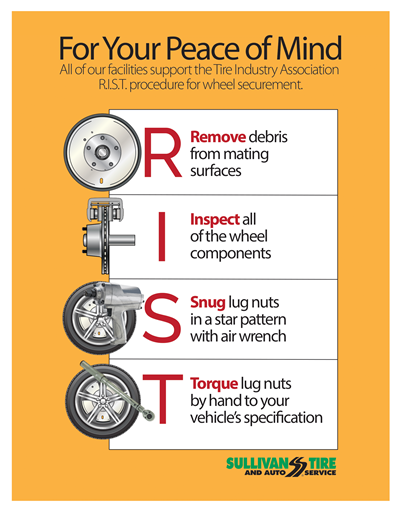

Wheel Securement

Sullivan Tire closely adheres to the RIST procedure outlined by the Tire Industry Association for wheel securement in all tire repairs, changeovers, and replacements.

Non-Repairable Tires

In some cases, the tire can't be repaired due to the location or severity of the damage. If the tire meets any of the non-repairable guidelines below, it's time to buy a new tire.

Puncture Outside Repair Area

- If the tire is punctured in any way outside of the Puncture Repair Area (see image), the tire cannot be repaired safely.

- True tire repairs are limited to the middle, or "crown" area of the tire.

- The crown is defined as the center of the tread, approximately 1 to 1.5 inches in from each shoulder. For most tires, the puncture repair area can also be defined by the first major groove on both shoulders.

Size of Puncture

- The maximum repairable injury size for passenger and light truck tires through load range E is 1/4 inch or 6mm in diameter.

- If the puncture in your tire is larger than the allowable repair size, the tire must be taken out of service.

Bulge or Bubble in Sidewall

- If there is a noticeable bubble in the sidewall of the tire, it has been damaged most likely by impacting a curb, pothole, or other types of road hazard.

- The resulting bulge or "bubble" in the sidewall is not repairable, and unfortunately, the tire must be taken out of service.

Say "No" to Tire Plugs

A tire plug is a sticky, expandable object that gets pushed into the damaged area of the tire from the outside and is adjusted until the air is no longer leaking from the tire. Although the leak may stop, it is easy to believe that the tire is repaired and good to go; unfortunately, that's not the case. Tire plugs are a quick fix and can fail over time. They can also potentially cause air to become trapped between the layers of tread, eventually causing the tread to separate, resulting in needing to buy a new tire.

Industry Standards for Tire Repairs

The U.S. Tire Manufacturers Association (USTMA, formerly known as Rubber Manufacturers Association) and Tire Industry Association (TIA) standards:

- Repairs cannot overlap. A rubber stem, or plug, must be applied to fill the puncture injury and a patch must be applied to seal the inner liner. A common repair unit is a one-piece combination unit with a stem and patch.

- Not all tires can be repaired. Specific repair limits should be based on recommendations or repair policy of the tire manufacturer and/or type of tire service.

- NEVER repair a tire that has an existing, improper repair; the tire must be scrapped.

- A plug by itself or a patch by itself is an unacceptable repair.

- NEVER perform an outside-in tire repair or on-the-wheel repair.

- The only way to properly repair a tire is to demount it from the rim so it can be inspected on the inside, remove the damaged material, fill the void with rubber, and seal the inner liner with a repair unit.

- A plug by itself or a patch by itself is not an acceptable repair because the plug does not permanently seal the inner liner and the patch does not fill the void left by the penetrating object, which allows water to enter the body of the tire and start corroding the steel belts.

- The use of sealants or emergency inflators that contain a sealant are not recommended as long-term solutions to a flat tire for the same reasons.

- Puncture repairs are limited to the center of the tread area. If there are punctures or damage in the shoulder or sidewall of the tire, it is not repairable.

- If the injuries are close enough so that the repairs overlap or the injuries are directly across from each other, the tire cannot be repaired and must be scrapped.

- Never repair tires with a tread puncture larger than ¼-inch (6mm).

Sullivan Tire closely adheres to the RIST procedures outlined by the Tire Industry Association for wheel securement:

Book Your Appointment Online

Easily request an auto or tire service on our website today!

Request an AppointmentRelated Articles